Trexel delivers some unique advantages to the consumer goods industry beyond just cost reduction, design freedom, and sustainability. MuCell® enables manufacturers to produce lightweight products without compromising strength and durability. The foam structure reduces the overall weight of the product, making it easier to handle, transport and use.

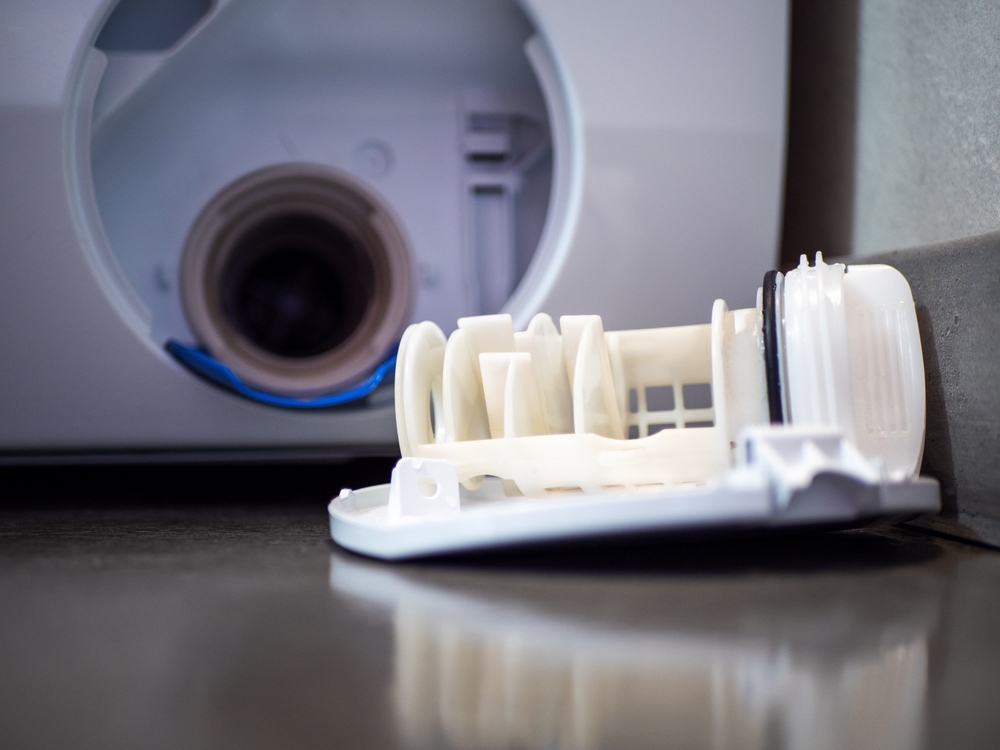

Household Appliances

MuCell® foam has been utilized in the production of household appliances like washers, dryers, refrigerators and vacuum cleaners. The lightweight and improved mechanical properties of MuCell® foam contribute to energy efficiency and product performance.

Sporting Goods

MuCell® foam has been used in the manufacture of sporting goods such as helmets, protective gear and equipment. The enhanced properties of MuCell® foam provide better impact resistance and increased safety.

Revolutionizing Consumer Products

Overall, MuCell® technology has revolutionized the Consumer products industry by offering lightweighting, cost-effective, and high-performance solutions. Its ability to improve product properties, reduce material usage and enhance sustainability makes it a valuable innovation in the manufacturing sector.

Injection Molded Consumer Goods

The MuCell® process provides many unique characteristics in injection molded consumer goods. Below are a few of the many benefits businesses will see using Trexel technology in their product creation:

Automotive

Automotive

The Automotive market has been Trexel’s core industry since our beginning, and there have been thousands of automotive parts realized in commercial production with MuCell® technology.

Electronics

Electronics

Trexel’s microcellular foaming technology has been used in paper path components for copiers and printers for the past 20 years. Adoption has primarily been driven by improvements in dimensional stability which is critical to movement of the paper through the device and print quality.

Footwear

Footwear

Trexel has been at the forefront of foaming applications to facilitate the conversion from established EVA chemical foaming processes to the use of thermoplastics TPU physical foaming for the production of shoe mid-soles.

Industrial

Industrial

Trexel’s foaming technologies are used in many diverse industrial applications from shipping pallets to crates to buckets, to power tools and more.

Medical

Medical

Plastics play a major role in healthcare, especially in the manufacturing of large and small medical devices. Trexel’s lightweighting technology has become more and more important to the industry.

Packaging

Packaging

Trexel’s P-Series MuCell® system is specifically designed to meet the unique processing demands of brand owners striving to meet cost reduction and sustainability goals.

Let’s Make it Happen

Don’t hesitate to reach out to our global team.

We’re here to assist and provide you with answers to all of your inquires. Let’s take a look at your application and discuss whether our technology can help you reduce costs AND your carbon footprint. We are eager to guide you through the process. Get in touch today!

By Phone:

781-932-0202

By Email:

info@Trexel.com