Each project starts with an idea for a new product or problem-solving approach. We offer our expertise and know-how to move you from concept to successful implementation. Our in-house experts collaborate seamlessly with a network of reliable partners to help you through your project.

Free Feasibility Analysis

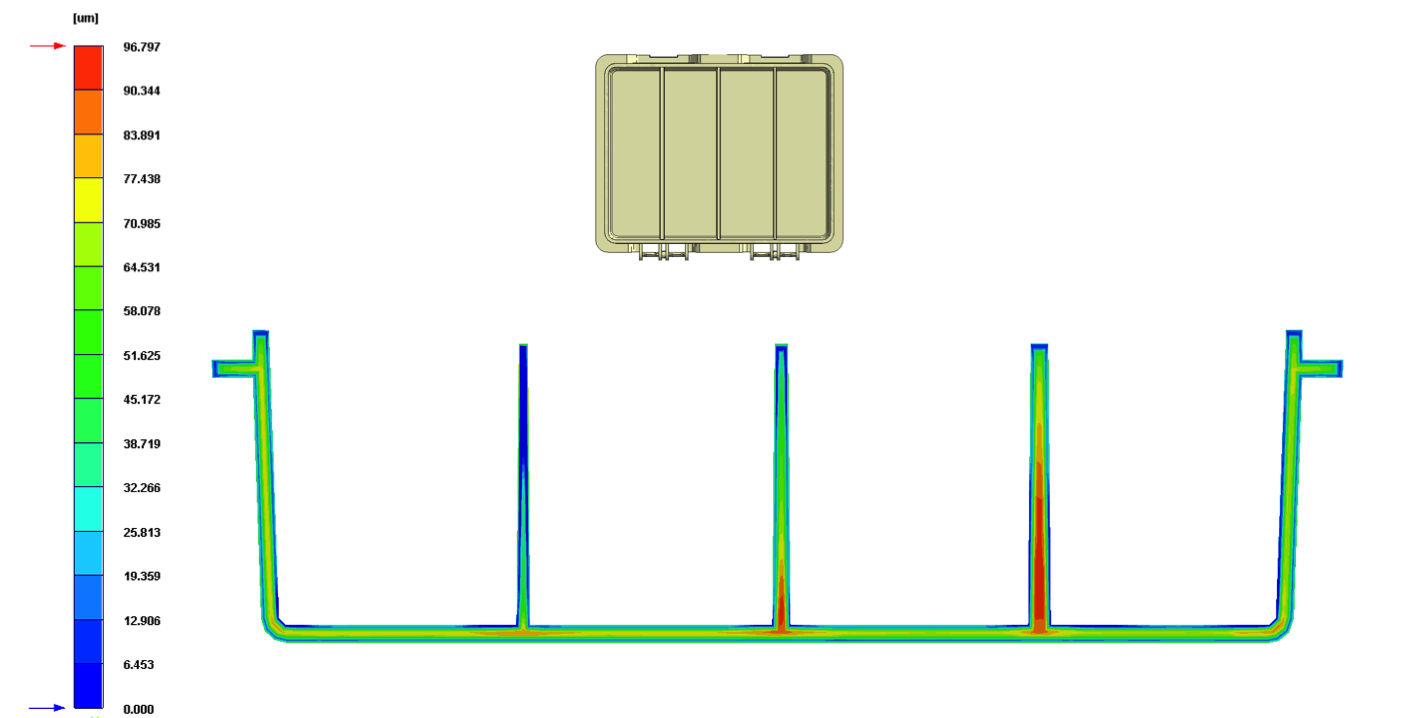

Here we take a more in-depth look at your particular application. We analyze wall thickness, gate positions, and flow lengths in order to give you a more refined estimate of the weight, cycle, and clamp force savings if you run your part with a MuCell® gas system. We also point out limiting features of your current design and provide an estimate of the impact of foaming-specific design improvements.

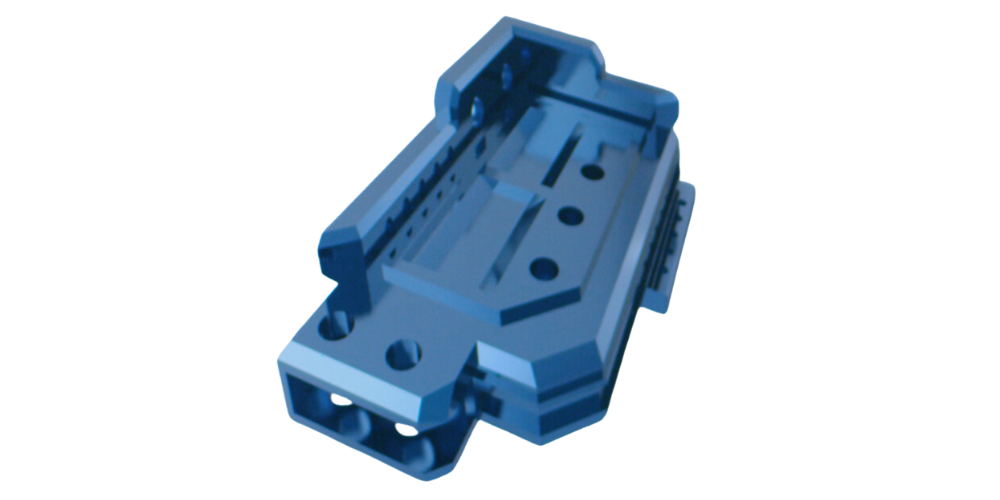

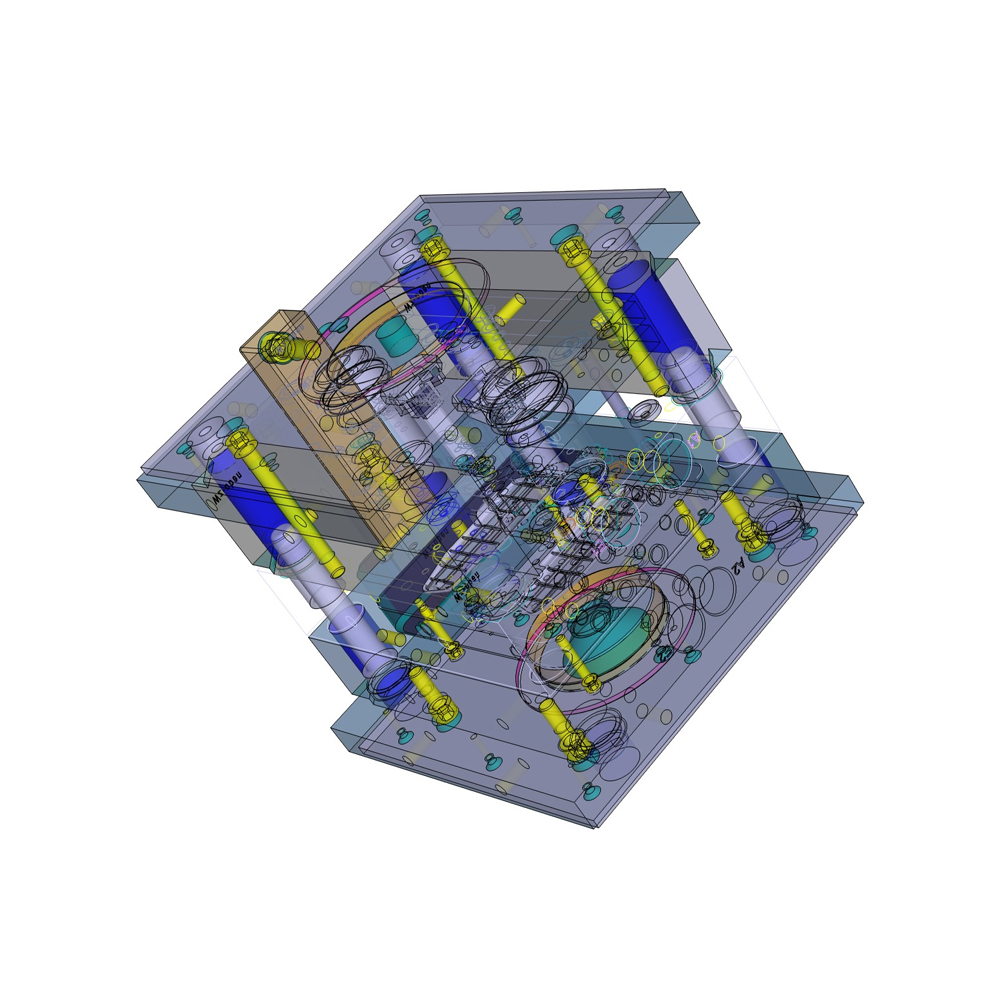

Tool Design and Sourcing

In addition to part design, we also offer tooling design and mold sourcing, providing a full turnkey solution for our customers.

Part Design/ Optimization

We provide full design services in order to either optimize your existing part design for foaming or develop a new part design. Our vast foaming experience enables us to ensure that your part is optimally designed for foaming, achieving maximum weight, cycle, and clamp force benefits.

Simulation Services

Trexel and 2LIMIT can provide simulation services using Moldex 3D, and we are developing full FEA capability for MuCell® –foamed parts.

Foaming Evaluation and Implementation Consultation

As a first step we check if your product/idea is a good candidate for foaming and provide a rough estimate of weight, cycle time and clamping force savings based on our experience with similar applications.

Trexel will support you by consulting on your options for MuCell® implementation at your site. We can evaluate your existing equipment and/or provide options for investing in a new integrated MuCell® system from our proven Injection Molding Machine partners.

Let’s Make it Happen

Don’t hesitate to reach out to our global team.

We’re here to assist and provide you with answers to all of your inquires. Let’s take a look at your application and discuss whether our technology can help you reduce costs AND your carbon footprint. We are eager to guide you through the process. Get in touch today!

By Phone:

781-932-0202

By Email:

info@Trexel.com