Evaluating the Effect of the MuCell Process on Components Made of Long Glass Fiber Polypropylene Materials

Summary:

The purpose of this study is to address the question about the relevant effect of the MuCell Process on the impact properties of a long glass fiber molded component such as a door module. The testing technique chosen to identify this affect is multi-axial impact testing.

Multi-axial impact testing of Celstran PP GF40-04 injection molded as solid plaques and those 10% weight reduced with the MuCell Process show that the peak loads absorbed by both test specimens are equal. The parts produced with the MuCell Process show lower energy absorbed as the samples show a reduction in deflection as compared to the solid parts.

The fact that the peak loads to failure are the same indicate that a solid part design to withstand a set of static loads in use can be converted to a MuCell part at a weight reduction of 10% or less, and function in the same manner as the solid design. It is also expected that in the case of an impact event, both the solid and MuCell components would fail with the MuCell component absorbing about 20% less energy.

Discussion:

Multi-axial impact testing (ASTM D3763) is a procedure where by a plaque is supported by a 3 inch ring and a ½” diameter dart is driven through the plaque with a given force. The output or results is a graph of the load applied vs time curve with the reported values being deflection at peak load, peak load, energy at peak load and total energy absorbed. The test is always to failure and the failure is categorized as either ductile or brittle.

Multi-axial impact testing can be envisioned as the ability of the polymer (and any added fillers) to stress relax or flow over an extremely short period of time before fracturing. The degree of brittleness of a polymer is related to the amount of stress relaxation happening in a very small region directly under the impact dart. This micro region motion or flow is greatly affected by any imperfection and micro-voids including the interfaces between polymers and fillers. Due to the high speed nature of the multi-axial impact test, load is not distributed across the test specimen in the way it is with low speed tests such as tensile and flexural testing. As such, full part impact testing is more closely related to a combination of tensile and flexural properties due to the fact that the event is typically spread across a large surface area and includes the transfer of loads to attachment points. For this reason, part testing is always the preferred method of comparing solid parts to MuCell parts

Tests were run with 2.25 mm thick 5” x 5” plaques produced using 40% long glass fiber PP as solid and at a 10% density reduction with the MuCell Process. A second variable introduced for the testing was the dart diameter, the standard 0.5 inch diameter dart and a 1 inch diameter dart.

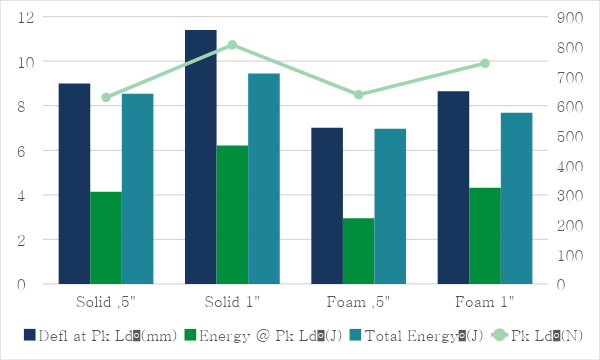

The results of the two dart geometries were as expected, the larger dart diameter resulted in higher load and energy numbers. This is due to the fact that the impact is spread across a larger area and also because the clearance between the support ring, a 75 mm ring, and the dart OD is less resulting in a more rigid support. The trends for the solid parts going from a 0.5 inch dart to a 1 inch dart and parts produced with the MuCell Process with increasing dart diameter were similar, deflection at peak load increased by about 20%, energy at peak load increased about 32% and the total energy absorbed increased by 10%. The increase in peak load going from a 0.5 inch support ring to a 1 inch support ring was greater for solid parts than for the MuCell parts (22% and 14% respectively)

Table 1: Dart Geometry – Solid Parts

| Defl at Pk Ld | Pk Ld | Energy @ Pk Ld | Total Energy | |

| Sample | (mm) | (N) | (J) | (J) |

| Solid .5″ | 9 | 628 | 4.14 | 8.54 |

| Solid 1″ | 11.4 | 805 | 6.21 | 9.45 |

| % Change | 21.05 | 21.99 | 33.33 | 9.63 |

Table 2: Dart Geometry – Foam Parts

| Defl at Pk Ld | Pk Ld | Energy @ Pk Ld | Total Energy | |

| Sample | (mm) | (N) | (J) | (J) |

| Foam .5″ | 7.01 | 637 | 2.95 | 6.97 |

| Foam 1″ | 8.65 | 743 | 4.32 | 7.69 |

| % Change | 18.96 | 14.27 | 31.71 | 9.36 |

The second comparison is between the solid samples and the MuCell samples. Using both the ½” and the 1” dart, the total energy for the MuCell samples was about 20% lower than for the solid samples. However, the average load for the solid and the MuCell samples were about the same. The difference in total energy resulted from the fact that the average deflection which was about 30% higher for the solid samples as compared to the MuCell samples.

Table 3: Solid vs Foam at 0.5” Dart

| Defl at Pk Ld | Pk Ld | Energy @ Pk Ld | Total Energy | |

| Sample | (mm) | (N) | (J) | (J) |

| Solid .5″ | 9 | 628 | 4.14 | 8.54 |

| Foam .5″ | 7.01 | 637 | 2.95 | 6.97 |

| % Change | -28.39 | 1.41 | -40.34 | -22.53 |

Table4: Solid vs Foam at 1” Dart

| Defl at Pk Ld | Pk Ld | Energy @ Pk Ld | Total Energy | |

| Sample | (mm) | (N) | (J) | (J) |

| Solid 1″ | 11.4 | 805 | 6.21 | 9.45 |

| Foam 1″ | 8.65 | 743 | 4.32 | 7.69 |

| % Change | -31.79 | -8.34 | -43.75 | -22.89 |

These results indicate that a part produced with the MuCell Process using LGF PP should withstand the same loads (no change in peak loads) as the solid sample. However, when the peak loads are exceeded, the MuCell part will fail with less deflection. In addition, these relationships hold constant regardless of the geometry of the dart.

Translated into part performance, it is expected that a solid part designed to function under a certain load condition should perform similarly when converted to a MuCell part. In a door panel, this would indicate that a solid door panel converted to the MuCell Process should perform equally well in supporting the necessary components as the solid equivalent. However, when the part undergoes a load that exceeds the capabilities of the material, typically a load not seen during normal use, the MuCell part will fail at a lower deflection where as the solid part will absorb more energy and deflect further before total failure occurs.

Diagram 1:

Conclusion:

It is expected that a solid part designed to withstand a set of static loads in use can be converted to a MuCell part at a weight reduction of 10% or less and function in the same manner as the solid design. It is also expected that in the case of an impact event, both the solid and MuCell components would fail. While the MuCell component would absorb about 20% less energy during the impact event, this would not be significant given the typical surrounding metal structure.