Important Update: ENGEL Acquisition of Trexel

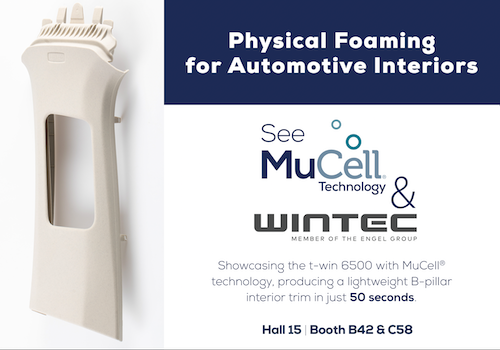

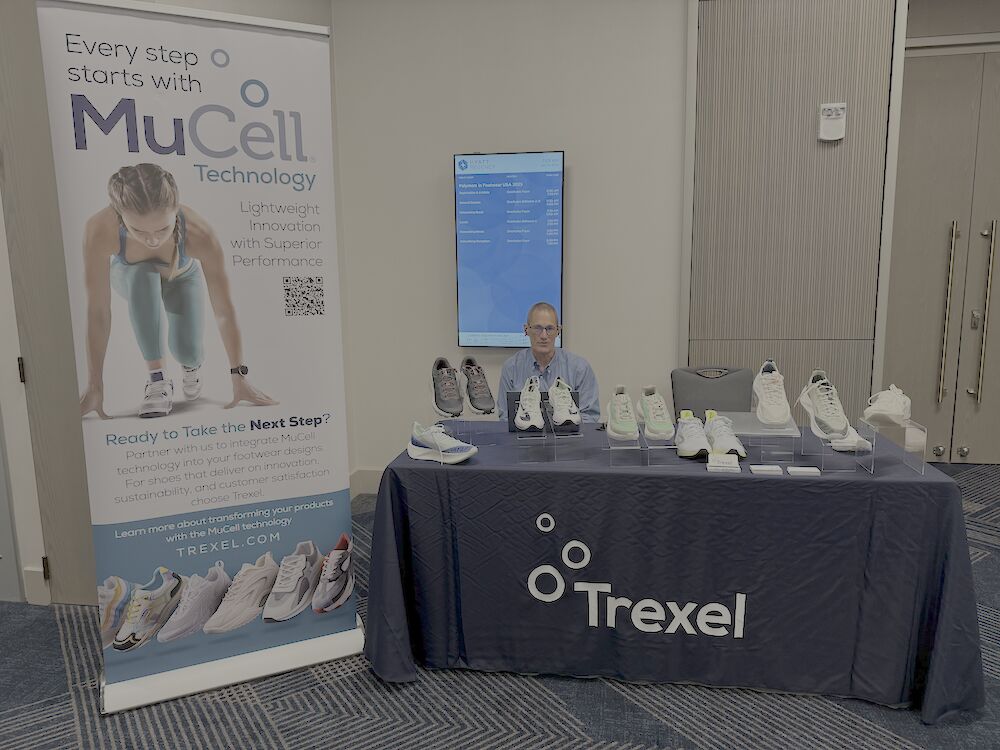

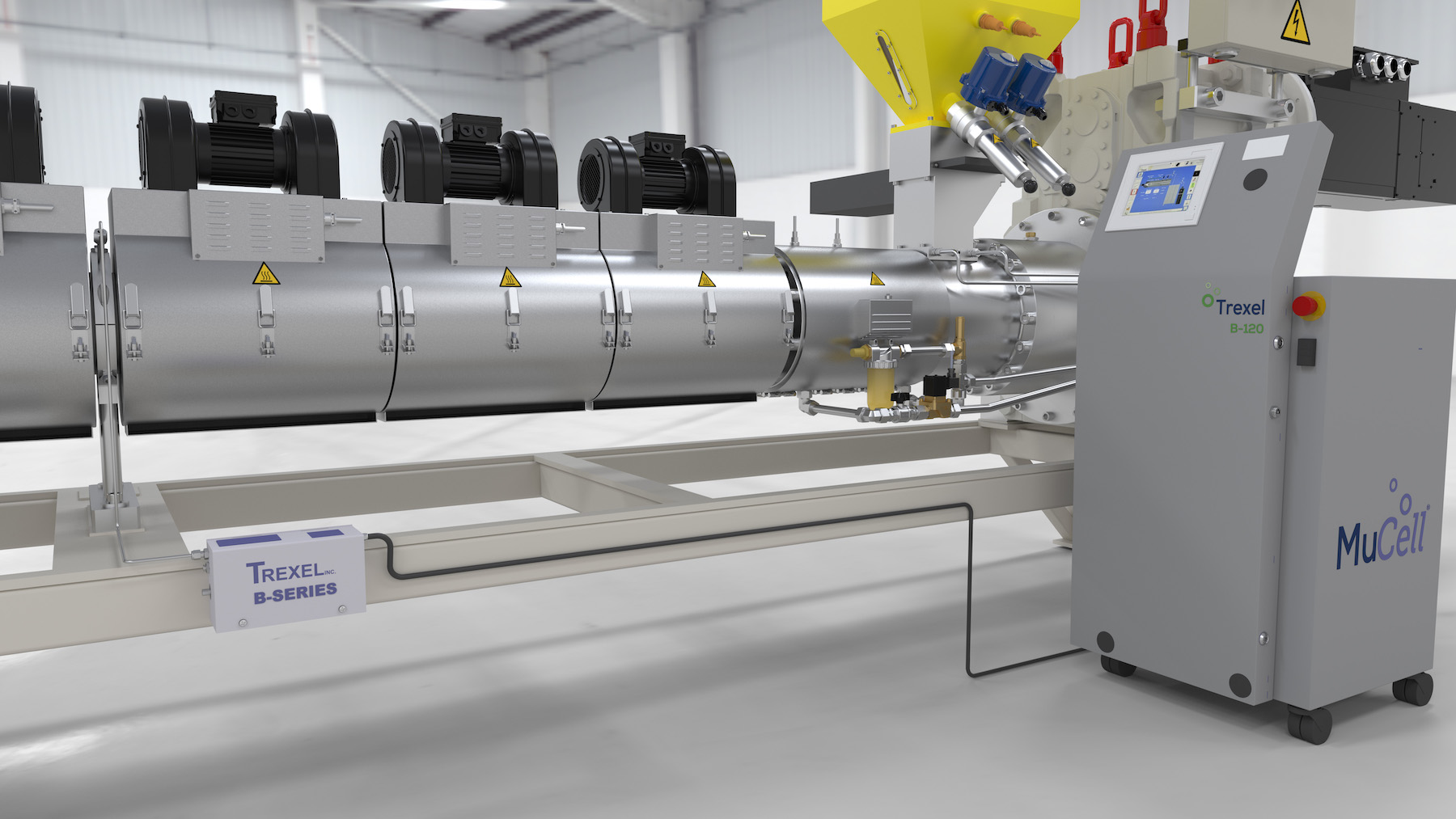

As a valued customer of Trexel, we are pleased to share an important update regarding TREXEL'Sfuture. ENGEL, a globally recognized injection-molding company with a long-term mindset anda strong commitment to innovation has made an investment in TREXEL. This investment is aimedat strengthening TREXEL's leadership in microcellular foaming technology and ensuringcontinuity and reliability for Trexel's customers.TREXEL will [...]