Trexel has been at the forefront of foaming applications to facilitate the conversion from established EVA chemical foaming processes to the use of thermoplastics TPU physical foaming for the production of shoe mid-soles. This effort goes back more than 10 years, with the first commercial introduction by New Balance and operating volumes in excess of 1,000,000 parts per year. Today MuCell foaming is being applied in several shoe manufacturers around the globe for development and production.

New Balance is a registered trademark of New Balance Athletics, Inc. All rights reserved.

Know-How and Technical Strengths

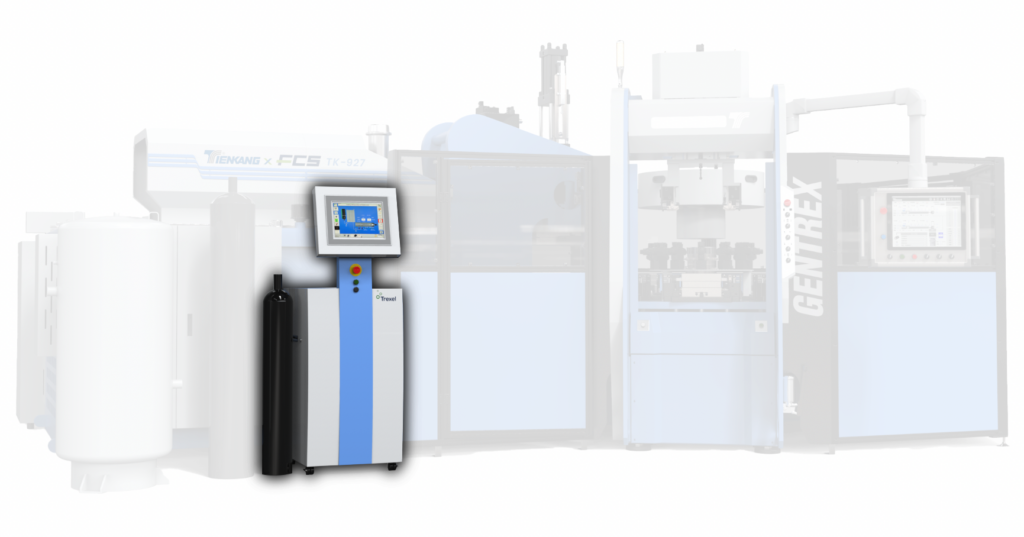

Learn how Trexel is enabling the production of thermoplastic midsoles in the footwear industry and accelerating transitions from cross-linked elastomers. Trexel’s proprietary variable dosing system permits manufacturers to run a greater range of midsole sizes with repeatable densities and shapes on the same machines. In addition, Trexel’s collaboration with TienKang and FCS (Fu Chun Shin Machinery Manufacturing Co., LTD), provides a totally integrated automation solution with high quality midsoles as low as 0.2 g/cc densities. Check out TienKang’s innovative GENTREX automated production system, with authorized key technology, keeping you ahead of the industry.

Powered by MuCell® Technology

Trexel’s MuCell® SCF foaming technology revolutionizes the footwear industry by introducing unparalleled physical foaming capabilities. Adopting MuCell® technology will allow you to successfully blend supercritical nitrogen (N2) or CO2 into molten thermoplastic materials. Trexel’s solution propels you forward into the era of the circular economy. Experience a comprehensive molding solution that can improve cushioning, support and comfort.

Key Advantages of MuCell® Technology

Automotive

Automotive

Automotive has been Trexel’s core industry since our beginning, and there have been thousands of automotive parts realized in commercial production with MuCell® technology.

Consumer

Consumer

Trexel delivers some unique advantages to the consumer goods industry beyond just cost reduction, design freedom, and sustainability. MuCell® enables manufacturers to produce lightweight products without compromising strength and durability.

Electronics

Electronics

Trexel’s microcellular foaming technology has been used in paper path components for copiers and printers for the past 20 years. Adoption has primarily been driven by improvements in dimensional stability which is critical to movement of the paper through the device and print quality.

Industrial

Industrial

Trexel’s foaming technologies are used in many diverse industrial applications from shipping pallets to crates to buckets, to power tools and more.

Medical

Medical

Plastics play a major role in healthcare, especially in the manufacturing of large and small medical devices. Trexel’s lightweighting technology has become more and more important to the industry.Packaging

Packaging

Trexel’s P-Series MuCell® system is specifically designed to meet the unique processing demands of brand owners striving to meet cost reduction and sustainability goals.

Let’s Make it Happen

Don’t hesitate to reach out to our global team.

We’re here to assist and provide you with answers to all of your inquires. Let’s take a look at your application and discuss whether our technology can help you reduce costs AND your carbon footprint. We are eager to guide you through the process. Get in touch today!

By Phone:

781-932-0202

By Email:

info@Trexel.com