The Science Behind TecoCell®

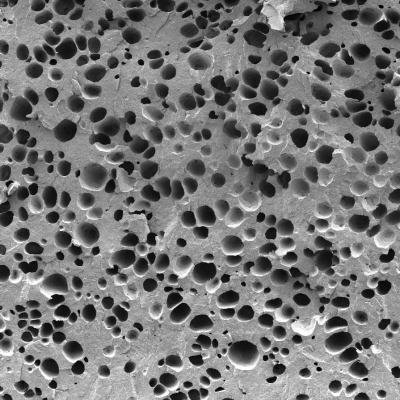

TecoCell®, which is produced through a specialized and patented process, creates a homogeneous gas/cell matrix by utilizing uniform size CaCO3 particles of .08 microns.

The CaCO3 nanoparticles distribute themselves evenly in the material system, resulting in a strong and constant cell structure throughout the blow molded or injection molded part. The uniformity of the cell gives the user a lightweight part with low warpage, faster cycles times, better stiffness and higher heat distortion properties.

This even distribution and small cell size of the TecoCell® additive is especially effective in unfilled PP and PE materials. These materials are commonly used for blow molded automotive ducts and injection molded thin-wall packaging.

Smallest Cells = Greatest Benefits

TecoCell® technology produces the smallest cell size achievable (50 – 200 microns) through the exclusive use of nano-sized, (<=0.08 micron) CaCO3 particles.

TecoCell’s cell size and uniform distribution result in superior mechanical properties and surface appearance compared to conventional chemical forming agents.

Easy to Test and Implement

TecoCell® provides immediate cost savings and improvements that can be proven out during a short mold trial. Contact Trexel today to discuss how TecoCell® can benefit your specific application. A complimentary sample of TecoCell® and remote trial support will be provided on applications determined to be good candidates.

Cleaner, Greener Chemistry

TecoCell® chemistry is a cleaner process. All ingredients in the TecoCell® formulation and their reaction products are environmentally friendly. CO2, water and citric salts, all inert and benign, are the only by-products. In contrast, traditional chemical foaming agents produce hazardous by-products that can corrode molds and are environmentally harmful.

Cleaner, Greener Chemistry

TecoCell® chemistry is a cleaner process. All ingredients in the TecoCell® formulation and their reaction products are environmentally friendly. CO2, water and citric salts, all inert and benign, are the only by-products. In contrast, traditional chemical foaming agents produce hazardous by-products that can corrode molds and are environmentally harmful.

Processing Advantages with TecoCell® Chemical Foaming Agents

Let’s Make it Happen

Don’t hesitate to reach out to our global team.

We’re here to assist and provide you with answers to all of your inquires. Let’s take a look at your application and discuss whether our technology can help you reduce costs AND your carbon footprint. We are eager to guide you through the process. Get in touch today!

By Phone:

781-932-0202

By Email:

info@Trexel.com