Sam Dix, R&D director at Trexel Inc., dissects Trexel’s expansion into the foamed blow moulding space for consumer packaging in response to challenging new sustainability targets.

Key Highlights:

- The EU has seen a significant rise in packaging waste, prompting legislation to enforce a circular economy approach, aiming for at least 35% recycled content by 2040.

- In October 2023, ENVI adopted a proposal that stated that general packaging should contain at least 35% content recovered from post-consumer sources.

- Trexel is adapting its solutions to meet sustainability targets, including foaming beverage containers and entering the blow moulding space for consumer packaging, offering cost-effective and sustainable options.

The use of recycled plastic materials is a critical factor in the move towards a fully closed-loop economy in the plastic industry. Between 2009 and 2020, the total mass of packaging waste generated in the EU rose by 20%. The packaging and packaging waste division (PPWD-Directive 94/62/EC) lays out measures to prevent such waste to encourage the reuse of such packaging.

The proposals are designed to reduce the disposal of packaging waste and promote a fully circular economy. In October 2023 the European Parliament committee on the environment, public health and food safety (ENVI), adopted a proposal that stated that general packaging should contain at least 35% content recovered from post-consumer sources, rising to 65% by the same date in 2040. This report proposal was voted in favour by a majority of 68% by EU Parliament in November 2023.

Bottle foamed by 20% by weight, 3 layer, with 50% PCR.

The governing EU council then adopted the ENVIs negotiating position in December 2023. The consensus is that this will become not just a directive but a full legislation. This is part of a wider initiative to reduce waste per capita by 10% by 2030 and 20% by 2040.

Some of the wider objectives include changes to the recycling and reuse of wood, metals and glass, as well as providing initiatives in plastics to not only recycle but to also refill items like beverage containers at the point of sale. It is not just PET bottles that are being targeted. These targets are set to follow over the Atlantic and beyond in coming years with some states already in the USA following suit.

With such aggressive targets and time-sensitive goals in the headwinds, producers are concerned about implementation and costs associated with such developments. Not only will supply and demand of raw materials be a major issue borne on the resin suppliers, but also the availability of appropriate technology to ensure processes and products are cost-competitive and do not contribute to costs passed on to the consumer in times of high inflation.

These measures have been long in the making and Trexel has been preparing an array of technology options using its MuCell trademarked technology. Trexel has built a reputation as a main physical foaming solution in injection moulding and has had great success to date in automotive and industrial foamed goods to reduce product weight, clamp tonnage (wear on the mould) as well as improving dimensional stability by eliminating sink and warp.

Additionally, because the technology allows thin to thick foaming along the flow path, moulds can be redesigned to remove even more weight. These physical foaming systems can be purchased as options for most injection moulding OEMS in the market around the globe. Trexel also sells a patented chemical foaming solution that boasts a superior surface appearance, but is used for lower weight reductions where the focus is to purely eliminate sink marks and warp.

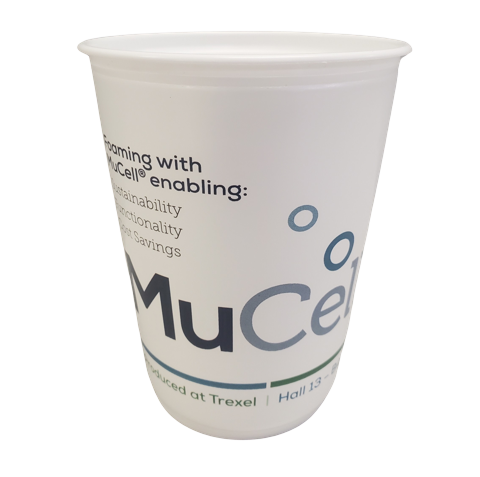

In direct response to the new legislation proposals, Trexel has leveraged its technology to provide foaming of beverage containers for reusable cups. These can be foamed down to a density of 200kg/m3 and provide the correct insulation for hot beverages whilst having enough integrity to be reused and refilled at the point of sale. This is something outlined in the directive, such that 20% of beverages filled at the point of sale available in reusable packaging will be 20% by 1st Jan 2030 and 80% by 1stJan 2040. This technology was on display at Trexel’s booth at the K-Show in 2022 a collaboration with Arburg and Bockatech which it calls Ecocore.

Trexel has also entered the foamed blow moulding space for consumer packaging in addition to its portfolio of solutions for low-density automotive ducts. The consumer packaging blow moulding solution can be used to foam a 2 or more-layer bottle to reduce the overall weight of the part by up to 25% for a similar thickness as solid bottles with corresponding similar; top load, impact strength and ESCR properties. This is a game changer when incorporating 35% PCR content as per the legislation because the foaming can reduce the overall package price. For example, a bottle foamed 15% with the same wall thickness containing 35% proposed PCR at 1.5 times the cost of the solid can be produced at the same cost as the virgin solid, thus providing a very cost-effective and sustainable option that abides by the new legislation. Preferentially, the foaming also creates an opacity that enables off-white PCR grades to look white again without adding more tiO2 masterbatch.

The technology does require a multiple layer machine but the gas pumping system can be directly retrofitted by simply drilling a simple hole into the barrel. The solution can be applied to shuttle or wheel machines. There is no need to change other equipment. The technology revolves around a pump investment only and there are no license fees. Typical applications are; household goods, cosmetics and industrial containers. Trexel is working with W. Muller in Germany and USA to provide a turnkey solution. W Muller is a specialist in multilayer head technology for the processing of PCR, and the synergy of the two technologies lends itself well to creating the best possible foaming solution.

Trexel hot drink container foamed to a density of 250kg/m3.

In direct response to the new legislation proposals, Trexel has leveraged its technology to provide foaming of beverage containers for reusable cups. These can be foamed down to a density of 200kg/m3 and provide the correct insulation for hot beverages whilst having enough integrity to be reused and refilled at the point of sale. This is something outlined in the directive, such that 20% of beverages filled at the point of sale available in reusable packaging will be 20% by 1st Jan 2030 and 80% by 1st Jan 2040. This technology was on display at Trexel’s booth at the K-Show in 2022 a collaboration with Arburg and Bockatech which it calls Ecocore.

Trexel has also entered the foamed blow moulding space for consumer packaging in addition to its portfolio of solutions for low-density automotive ducts. The consumer packaging blow moulding solution can be used to foam a 2 or more-layer bottle to reduce the overall weight of the part by up to 25% for a similar thickness as solid bottles with corresponding similar; top load, impact strength and ESCR properties. This is a game changer when incorporating 35% PCR content as per the legislation because the foaming can reduce the overall package price. For example, a bottle foamed 15% with the same wall thickness containing 35% proposed PCR at 1.5 times the cost of the solid can be produced at the same cost as the virgin solid, thus providing a very cost-effective and sustainable option that abides by the new legislation. Preferentially, the foaming also creates an opacity that enables off-white PCR grades to look white again without adding more tiO2 masterbatch.

The technology does require a multiple layer machine but the gas pumping system can be directly retrofitted by simply drilling a simple hole into the barrel. The solution can be applied to shuttle or wheel machines. There is no need to change other equipment. The technology revolves around a pump investment only and there are no license fees. Typical applications are; household goods, cosmetics and industrial containers. Trexel is working with W. Muller in Germany and USA to provide a turnkey solution. W Muller is a specialist in multilayer head technology for the processing of PCR, and the synergy of the two technologies lends itself well to creating the best possible foaming solution.

The two companies have lab facilities in the USA, Germany can its technology can be tried.

Original Article published on Interplas Insights.